Chemical Processing Plants Air Purification

Air Scrubbing Solutions for Chemical Processing

The main IAQ challenge with chemical processing plants is the reagents used to carry out reactions. From organic solvents to acids and alkalies, these reagents can be deadly if they are not dealt with correctly. Clearly, chemical processing plants pose serious health risks to employees and those who live in the immediate area surrounding the plant. Organic solvents, if inhaled in high airborne concentrations, can cause severe headaches, nausea, loss of consciousness and in severe cases, death. Instances in which high airborne concentrations of vapor are present may increase the risk of respiratory infection and illness. Because reagents can be hazardous on their own, they can often create an equally noxious toxin during the reaction process.

A preliminary study conducted by Congressional aides found that cancer cases were much more rampant in areas located downwind of petrochemical plants. This study strongly suggests that both plant employees, as well as people living in surrounding areas, are all at risk of cancer.

Airbourne Toxins In Chemical Processing Plants

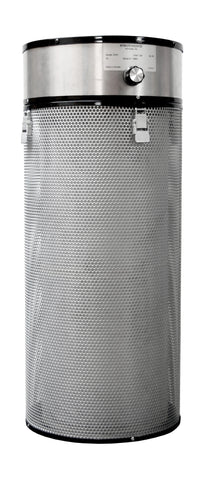

The handling of reagents in a chemical processing plant requires sufficient training and proper containment. Airborne toxins in chemical processing plants are often hard to contain and handle without a carefully equipped air filtration system in place. Electrocorp can handle the IAQ needs of chemical processing plants, even in extreme cases. Odor control and solvent fume removal problems are a cinch for Electrocorp air purification systems. Equipped with particle pre-filters, medical-grade HEPA and granular activated carbon, our industrial-strength air scrubbers are designed to handle even the most challenging IAQ problems. From stand alone units (like the RSU Series) to a module air scrubber (like the SSU), Electrocorp air purification systems adsorb air contaminants and release fresh air, even into adjacent rooms.